Stockforce for the Food&Beverage industry

Management of expiration dates, labeling and food traceability.

In detail

Stockforce is a software that allows you to completely manage the needs and issues of the food and beverage industry.

Expiration date management

StockForce allows you to address and resolve issues related to the expiration date of the product in its main meaning:

-Residual life of the product

-Minimum delivery deadline

The residual life of the product is understood to be the period between the date of shipment and the expiry date of the product itself. Some customers, for specific products or product families, may stricly require that the residual life of the product needs to be longer than a certain value. Obviously this parameter can vary from customer to customer and, for the same customer, from product to product or for the different product families.

By minimum delivery deadline we mean that some customers do not accept that a product has an expiry date lower than the expiry date of the last delivery for the same product.

StockForce allows you to define the life of the product for a specific customer or a category of customers, for a specific product or a category of products. It also allows you to define for which group of customers to activate the control of the minimum delivery deadline.

When the warehouse operator selects a specific lot, a validation will be performed and possibly rejects the lot if its expiry date is not consistent with the parameters described above.

Labeling

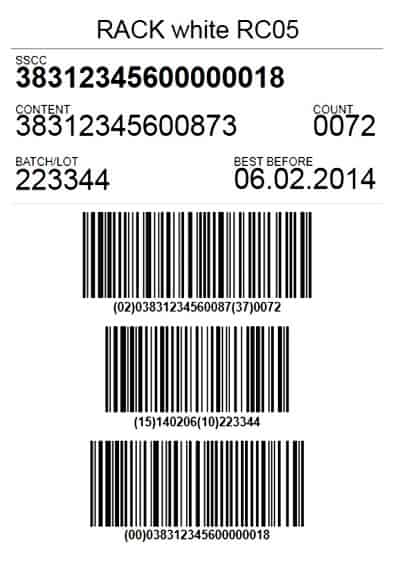

The GS1 labeling system is adopted internationally by the major large-scale distribution platforms and has therefore become a “de facto” standard for those who produce and market food products.

StockForce natively implements the reading and interpretation of labels that follow the GS1 standard. Furthermore, through our label printing service, it allows yo to produce labels that follow this standard in all phases of incoming goods handling (acceptance from suppliers, delivery from production).

StockForce answers all your needs

A traceability and logistics system for your company.

Rely on our experience to optimize warehouse processes.

Directive 2000/12/EC of the European Parliament and of the Council of 20.03.2000 and EC regulation No. 178/2002 of the European Parliament and of the Council of 28.01.2002 establish that starting from 01.01.2005 all manufacturing and marketing must adopt the appropriate procedures, explained in the aforementioned directive, in order to be able to identify and guarantee the traceability of agro-food products.

Food Traceability

Food safety is a responsibility that involves all the subjects of the “food chain”, the articulated path that food must take to reach our table. By food supply chain we mean the whole process that determines the production of a food product, what happens “from the land to the table”, from the raw materials to what we eat. The producers of raw materials, the companies that transform them into finished food, those who transport them, those who sell them and those who prepare them in public catering places: all these operators must follow precise rules, established by the competent authorities, to guarantee that the food itself is impeccable from the point of view of safety.

There is no doubt that product traceability is considered a real pre-condition for the new way of conceiving food supply chains.

This has the function of:

1. identifying any reponsibilities,

2. selectively withdraw a non-compliant product from the market,

3. guarantee the consumer on food safety.

The basic conditions for being able to trace a product are:

1. document the various steps taken along the supply chain;

2. have cognitive and methodical elements for instrumental assessments.

Stockforce and food traceability

StockForce guarantees the traceability of the products used both for companies that market food products (supplier – customer traceability) and, thanks to the production modules, for those that produce them (supplier – production line – customer traceability).

Stockforce in fact allows the company to define a batch for the finished product marketed which will be linked to all the batches of the components used for the produciton, in order to allow the complete identification of the single component used in the production batch. All traceability links are maintained by the system in order to achieve the following objectives:

- (from downstream to upstream), which is the ability to reconstruct the history and origin of a specific product batch.

- (from upstream to downstream), that is the ability to follow the production process from raw materials to the finished product by tracing the destination of a specific product batch.

Consultation and navigation of data is made extremely dynamic through appropriate dashboards that allow you to make full use of the data stored in the company archives.

Discover also our app for the sales network!

Book a demo

By clicking on “Send” you agree to the Terms and Conditions described in the privacy policy.